KEENAN helps facilitate greater efficiency & capacity at feed mill

Agricultural traders and suppliers RD Chesters Ltd. are on a mission to facilitate increased demand for locally sourced animal feeds and KEENAN are playing an important role.

RD Chesters has been supplying beef, sheep and dairy farms in Herefordshire and surrounding counties with feeds, seeds, fertilisers and harvest products for over two decades. Managing Director, Owen Thomas, talks through his business plan for expansion.

“I bought RD Chesters back in 2002 from David Chesters. Dave had a successful career locally and was a well-known name. We’ve expanded RD Chesters down the line of buying and selling on the merchant side of the business. In 2011, we decided to make use of the old farm buildings and put in a new farmyard for rearing calves from 2-6 weeks right the way through to finished bulls”.

“We’ve always made blends for ourselves on the back of growing our own cereals. As time went on, predominantly local farmers started asking us to do blends for them. We saw this as an opportunity to grow the business to sell blends from arctic-size delivered loads right the way through to totes. As our cattle numbers have increased to 1,300 and the potential for selling blends to customers has grown also, we saw the need for a more substantial mixer”, says Owen.

Owen explains the rearing and finishing system, which is also used as a way to refine the feed blend process.

“Chris Thorpe, an independent nutritionist, oversees the nutrition for our cattle and the blends we supply too. We start them off on our own Chesters Golden Maverick milk powder, which is 23% protein and 20% oil, along with a calf starter pellet. After about 2 weeks, we start graduating them onto our 16% grower blend. They stay on our 16% grower blend adlib until they reach 350 kilos. Then we transfer them onto the finisher ration over a couple of weeks which they stay on until they are slaughtered at 12.5 to 14 months. They are all fed with adlib straw and rock salt,” explains Owen.

“Based on what we look for with our own farming system, we want to offer a really practical performance-based ration with excellent local service”, says Owen. “For example, we will be able to do tote bags that can hold 1.2 tonnes of feed. 2.4 tonne is about the maximum of what you can tow on a truck and trailer, making it practical for people to collect. We want to offer little practicalities like that all the time.”

“Our customers also like the fact that we source our cereals and ingredients locally, and because we are mixing regularly, our mix is always fresh. This is all proven by our cattle which are here to see to give them a bit of confidence in what they’re buying,” says Owen.

Investment shows immediate pay-off

RD Chesters has made a bold investment to facilitate their continuing growth.

“To make us more efficient and to give us the opportunity to produce blends for the local market, we’ve recently invested in a new blending plant and the KEENAN ProMix machine.”

“Before this, we had a trailed High Spec wagon on a tractor. We liked the machine – it was simple and mixed well. On that basis, and given that I could see we were going to get a good service, we made the switch to KEENAN. The brand is well known, so I didn’t really need to be sold on the product,” explains Owen. “We have only just got it going, but so far so good. The whole side opens up and dumps the ration into a pit in less than half a minute which allows us to continually mix.”

“We need to get a few things refined, and we need to learn more than anything. Will Brocklehurst from InTouch is going to come out to us for another day to fine-tune our knowledge on the KEENAN. Our local service agent, Keith Evans, is really practical. He’s already suggested a couple of improvements to the set-up”.

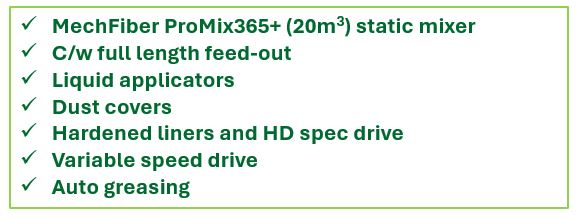

KEENAN ProMix machine specification