KEENAN Facilitate Increased Demand For UK Seaweed Fertiliser

Fast organic growth for UK seaweed fertiliser producers, Edwards Agricultural Supplies, led to the purchase of a fully custom-built KEENAN ProMix in a bid to rapidly scale up production to meet increasing demand.

Having used seaweed extract as a fertiliser on their own working farm since 1965, Edwards Agri Supplies are keen advocates of this natural alternative to conventional chemical fertilisers, which they have retailed since 1995 and produced since 2019.

Because of both economic and environmental factors, the practice of feeding soil with a seaweed-based solution rich in nitrogen, phosphorus, potash and trace elements, is becoming increasingly common.

‘UK Seaweed Fertiliser’ boasts a range of unique formulations used in agriculture, horticulture and gardens to stimulate healthy, vigorous and sustainable plant growth.

The product is endorsed by beef and sheep farmer and social media celebrity Gareth Wyn-Jones. He was quick to try the natural fertiliser alternative as he continually looks for answers to growing food in a sustainable way. Gareth sprayed half of his cutting grass field in spring 2023, and when silaging could visibly see the swaths of grass were much bigger than that of the untreated field.

Dave Edwards, also known and marketed as ‘Soil Dave’ in the horticultural world, is the brainchild behind this enterprise missioned to restore and preserve the health of productive soils in the United Kingdom and Ireland.

“The use of seaweed to grow plants traces back to the Stone Age. All food comes from the sea and from the land – that’s what I view as ‘surf and turf’! EASy Seaweed is a natural biostimulant that works by breathing life into the soil. It works with the soil, rather than against it”, says Dave.

“The seaweed feeds the soil biology in the soil – bacteria and fungi for example. The bacteria and fungi then go on to continually transport nutrients to the plant. This is unlike ammonium nitrate fertiliser which works for a short-term period and can leach by 30-80%, stripping carbon from the soil. We have got to replenish what we take – we can’t keep taking from the soil and not give anything back. With a healthier soil, plants are more resilient to disease and pests”, explains Dave.

The seaweed is sourced from the North Sea as part of a heavily regulated process before being blended with additional natural ingredients to increase bioavailable nutrients to feed both the plant and soil biology.

“Although it is undeniably the most important aspect to farm businesses, we’re not solely focussed on increasing yields. Our mantra is to grow food sustainably, and what I mean by that is without compromising the future health and productivity of the soil. Being sustainable and profitable goes hand in hand and we farmers are becoming more and more aware of this all the time”.

“The other huge benefit is the passive micronutrition of the crops fed to the animals. Cereals and forages that have been grown on seaweed fertiliser contain over 60 different trace elements and minerals which are available to the plant and consuming livestock, which is very important to the health of both and far more nutritious than plants fertilised with ammonium nitrate fertiliser” adds Dave.

How to use seaweed fertiliser

Seaweed fertiliser can be used to either replace or supplement conventional chemical fertilisers.

Edwards Agri Supplies recommend regular soil and tissue testing to establish a clear picture of soil quality before making an economically conscious land management plan. Following on from this, they also recommend applying the seaweed with EASy Bio-N, a natural soil bacteria that has been shown to assist with the transportation of nutrients to the plant.

“You don’t need to apply a lot of it because the bacteria within Bio-N multiply over time which can bring total input costs down” explains Dave. “On most extensive grazing systems, only one application is required in early spring and that will last the whole growing season. On more productive grass systems, we advise an additional application of seaweed post cutting. The soil structure, content, and what grows from it gets better year on year”.

KEENAN facilitate scaled-up production

In 2022, when fertiliser and other input prices reached a record-high, EASy UK Seaweed catapulted into the family-run business’ best-selling product range.

It was at this time that the team decided they needed to scale up production at their on-farm production site on the Herefordshire/Shropshire border through investing in a fully customised KEENAN ProMix industrial mixer.

“We’ve invested considerably into optimising the formulation, so were not prepared to compromise on a machine to process the formula. We had an old KEENAN Klassic100 for preparing feed for the cows, so knew how the machine worked and the back-up that came with it. With this in mind, we had the confidence to commission the KEENAN engineers to custom-build a machine for our very particular needs”, says Dave.

“On introducing the KEENAN ProMix to our production system, we went from manually producing 2,000-litres a day with two members of staff, to producing two 10,000-litres batches per day with 1 person overnight. To put this into perspective, 10,000-litres of Edwards Advanced seaweed fertiliser is enough to cover 5,000 acres”, adds Dave.

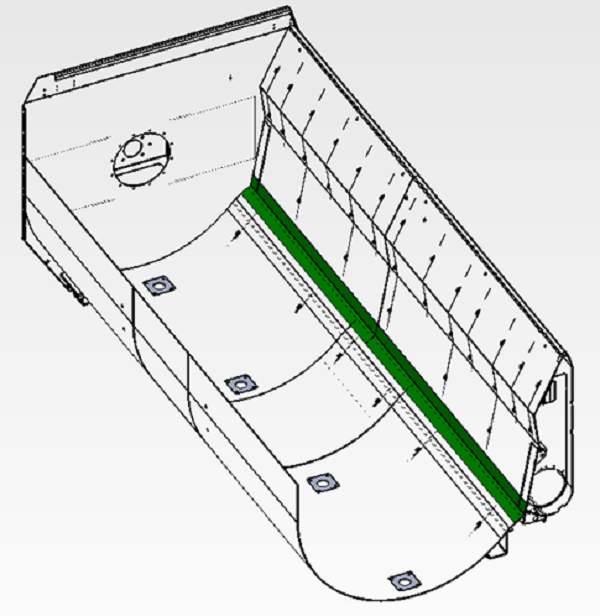

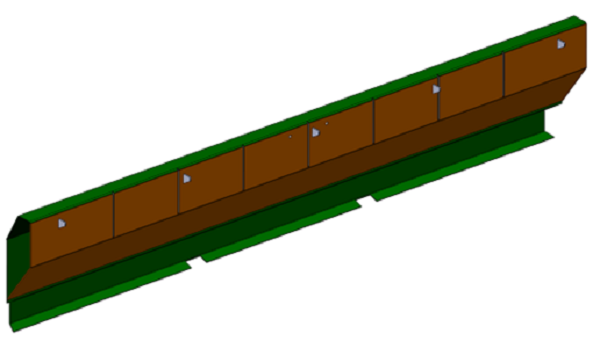

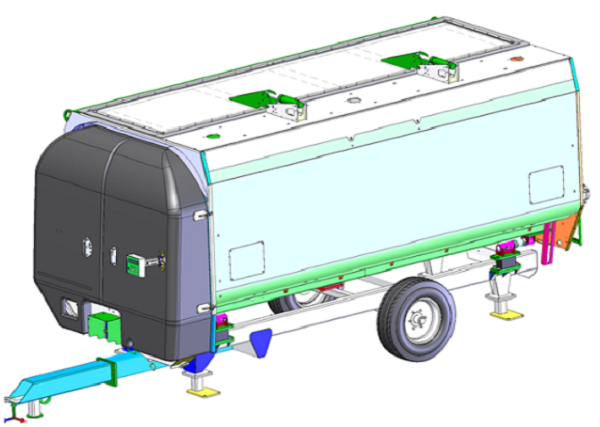

The custom-build KEENAN ProMix features a horizontal auger with angled paddles to stir, agitate and slosh the liquid from end to end to produce a homogeneous mix. But what was perhaps the most important aspect, are the seals fitted throughout to contain the liquid mix for long processing times.

Behind the scenes

Whilst KEENAN are market leaders in processing animal feeds into total mixed rations with the KEENAN MechFiber, KEENAN Vertical Auger and KEENAN Self Propelled ranges, the KEENAN ProMix machine is becoming increasingly prolific within a diverse range of custom-made industrial applications internationally.

Michael Conroy is dedicated to the ‘KEENAN Engineering Project’ team responsible for the design and manufacture of these highly customised machines and has been the project manager behind the custom KEENAN ProMix commissioned by Edwards Agri Supplies.

“On receiving the enquiry from the Royal Welsh Show last year, we immediately started planning the design of a machine to process the 10,000-litre liquid batches required by Edwards Agri Supplies. We were particularly excited by being part of a sustainable farming solution that closely aligns with the Alltech Planet of Plenty™ vision.

Six months later, following considered design, collaborative engineering and extensive testing, we delivered a machine that fulfilled the complex specification. Building a fully watertight machine was a first for us and therefore the most challenging aspect, but our accomplishment really proved our manufacturing capabilities,” says Michael.

Custom Engineering Specifications

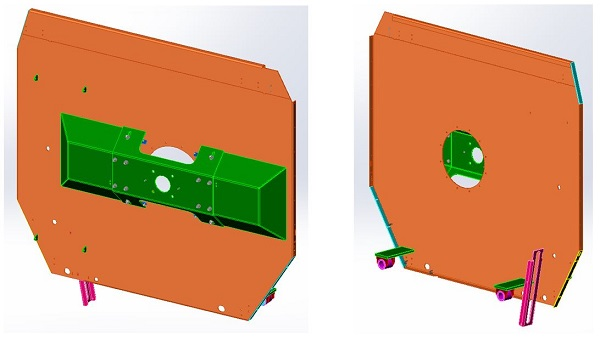

The 10,000-litre batch sizes brought the load level to well above the centre of the main rotor shaft. This wasn’t a problem for the KEENAN MechFiber but provided a new challenge when processing a 90 percent liquid mix.

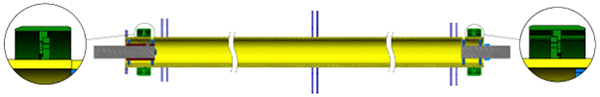

KEENAN being committed to continuous development, run numerous research and development projects. One such project being a new rotor/shaft seal solution developed in collaboration with SKF Seals Division. While not yet approved for mainstream production, the engineers were able to adapt this design and build a robust and unique sealing solution for this application.

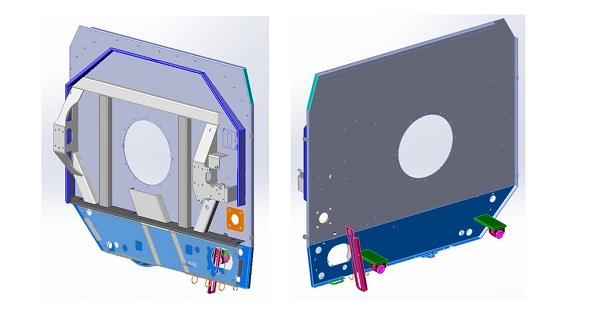

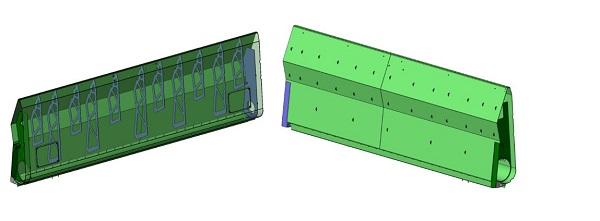

Body Shell

All panels on the body shell were customised to achieve complete watertightness. The standard KEENAN VFC door was replaced with a fixed fully sealed panel. The body has no blade mounting holes, the front and rear end panels were specifically designed to accept the custom rotor shaft seals.

Paddles

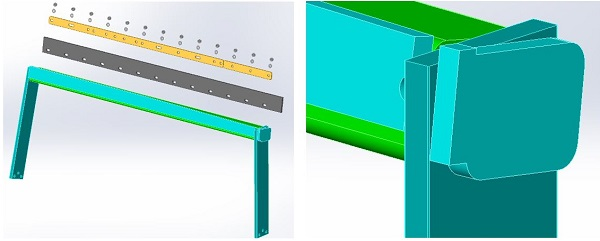

The application did not require the standard KEENAN body blades and castellated paddles but was fitted with the latest plus range 6° paddle concept. The design was further modified to accommodate the larger than standard special rotor shaft seals.

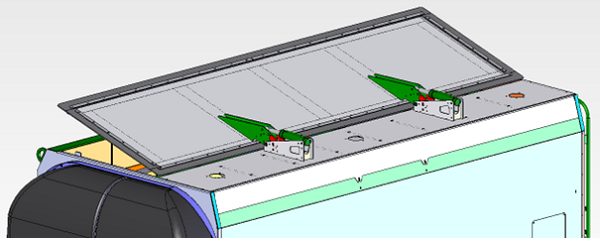

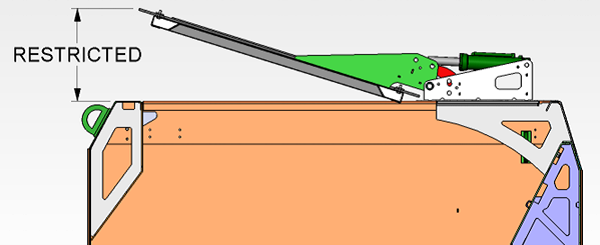

Hydraulic Cover

The top of the machine is covered with a large, hinged lid. Hydraulic cylinders allow it to be opened for loading powdered raw materials. Three separate 150 mm diameter fill points have been provided on the fixed section of the cover for loading liquid materials.

Outlets

Because the material is mainly liquid, the standard outlet chute and discharge auger on the side of the KEENAN were not required. Instead, KEENAN fitted four hydraulic controlled gate valves to the bottom of the belly. These connect via pipework to the next stage in EAS’s process. All hydraulic functions are connected to a central manual operated spool valve.

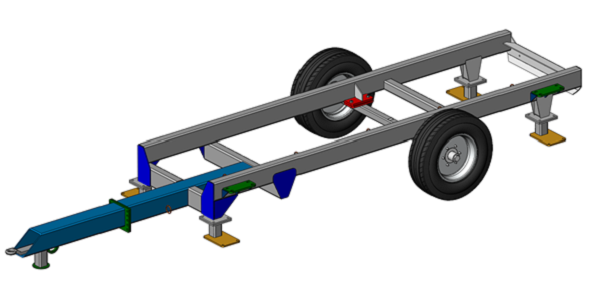

Chassis

The machine is a static unit which sits on four bolt-on legs, one in each corner. It is currently powered by tractor via a PTO but has capabilities to switch to an electric drive in the future. The chassis has been designed with special bolt-on components and interfaces to accommodate both drive options.

Technology

The machine has been fitted with the fourth generation InTouch controller to accurately guide and automate loading and processing.

“Engineering projects such as these are fast becoming a huge focus for the KEENAN business in response to an increased demand for our customisation capabilities. Our own internal expertise combined with specialist collaboration opportunities means that there is really no project too complex for us to deliver on,” concludes Michael.

If you have your own industrial project in mind speak to one of the KEENAN team today.